The Art of Handmade Shoes: A Journey Through the Craftsmanship and Process

Introduction to Handmade Shoes

Handmade shoes are more than just footwear; they are a testament to human skill and dedication. Unlike mass-produced shoes, each pair is crafted with meticulous attention to detail, ensuring a perfect fit and durability. The process involves multiple stages, each requiring specialized knowledge and tools. From selecting premium materials like full-grain leather to hand-stitching every seam, artisans pour their passion into every step. This commitment results in shoes that not only look exquisite but also provide unparalleled comfort and longevity. In today's fast-paced world, handmade shoes stand out as a sustainable choice, promoting slow fashion and reducing waste. By understanding the process, you can appreciate the value behind each pair and make informed decisions when investing in quality footwear.

Design and Pattern Making

The journey of handmade shoes begins with design and pattern making. Artisans start by sketching the shoe's shape, considering factors like style, function, and customer preferences. This stage is crucial as it sets the foundation for the entire process. Using traditional methods or modern software, they create precise patterns that will guide the cutting of materials. Each pattern is tailored to the individual's foot measurements, ensuring a custom fit. For example, a bespoke shoemaker might take multiple measurements, including arch height and toe shape, to create a unique last—the mold around which the shoe is built. This personalized approach eliminates common issues like blisters or discomfort, making handmade shoes a favorite among those with specific needs. By investing time in design, artisans ensure that the final product is both aesthetically pleasing and ergonomically sound.

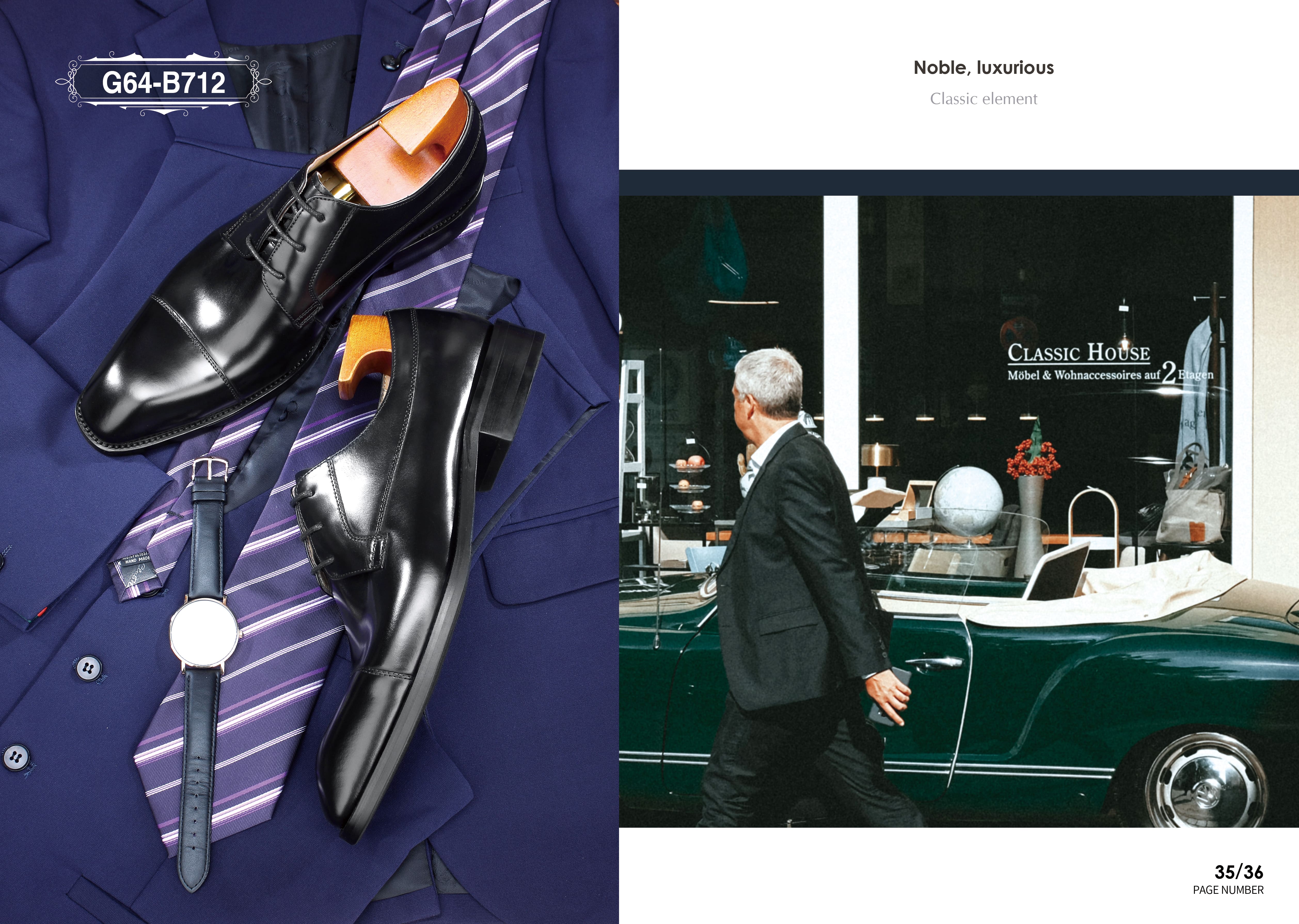

Material Selection and Preparation

Choosing the right materials is a key aspect of the handmade shoe process. Artisans typically opt for high-quality leather, such as calfskin or cordovan, known for its durability and natural beauty. Other materials like suede, exotic skins, or sustainable alternatives may also be used based on the design. Before cutting, the leather is inspected for flaws and conditioned to enhance its flexibility. This preparation step ensures that the material will hold up well during construction and over time. In addition to leather, components like soles, heels, and linings are carefully selected. For instance, leather soles are preferred for their breathability and ability to mold to the foot, while rubber soles offer better traction. By using premium materials, handmade shoes not only look luxurious but also perform better in daily wear, making them a worthwhile investment for long-term use.

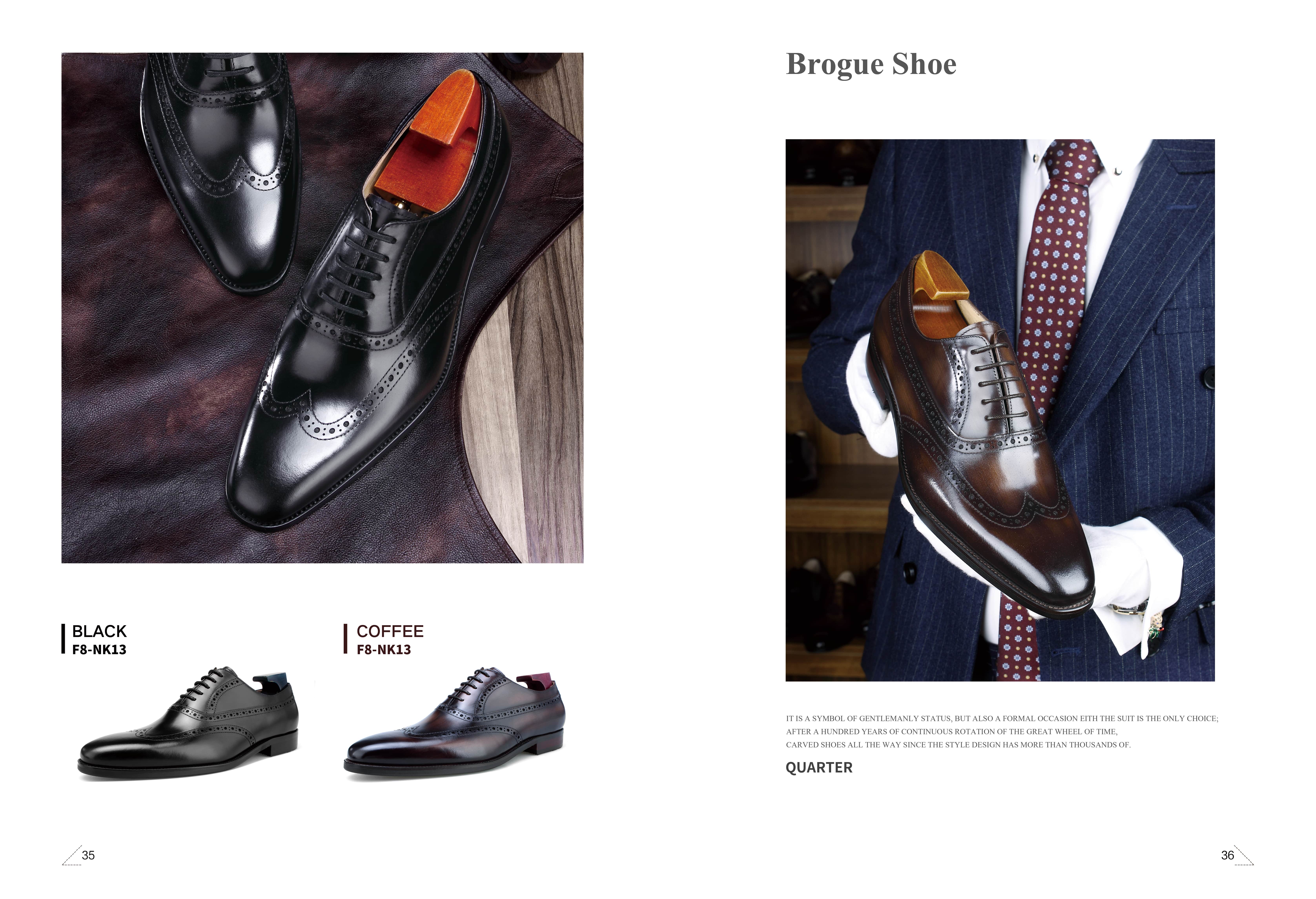

Cutting and Stitching

Once materials are prepared, the cutting and stitching phase begins. Artisans use sharp knives or dies to cut the leather according to the patterns, ensuring precision and minimal waste. This step requires a steady hand and years of experience to avoid errors. After cutting, the pieces are assembled through stitching, often done by hand using waxed threads. Hand-stitching allows for greater control and strength compared to machine stitching, reducing the risk of seams coming apart. Techniques like the Goodyear welt or Blake stitch are commonly employed, each offering different benefits in terms of durability and repairability. For example, the Goodyear welt method involves stitching the upper, insole, and welt together, creating a robust structure that can be resoled multiple times. This attention to detail in stitching not only enhances the shoe's longevity but also adds a unique, artisanal touch that sets handmade shoes apart from factory-made ones.

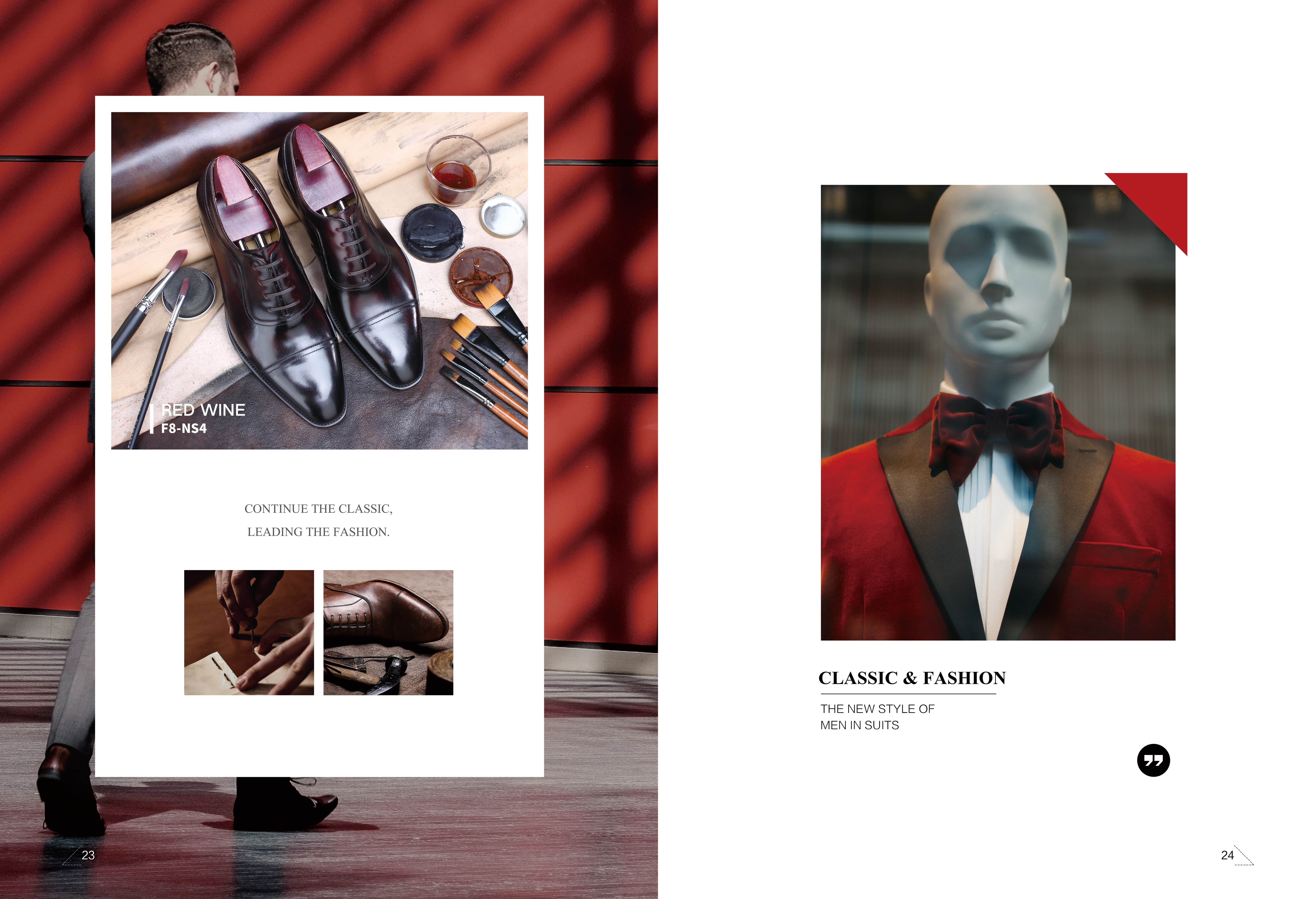

Lasting and Finishing

The lasting process involves stretching the upper leather over the last and attaching it to the sole, giving the shoe its final shape. This is a delicate task that requires skill to ensure a snug fit without distorting the materials. Artisans use tools like pincers and hammers to carefully mold the leather, often working in multiple stages to achieve perfection. Once lasted, the shoes undergo finishing touches, such as sanding, polishing, and adding decorative elements like broguing or burnishing. These steps not only improve the appearance but also protect the leather from wear and tear. For instance, a high-gloss polish can enhance the color and provide a waterproof barrier. Finally, the shoes are inspected for any imperfections before being packaged. This thorough finishing process ensures that each pair meets the highest standards of quality, ready to be worn with pride for years to come.

Common Questions

How long does it take to make a pair of handmade shoes?

The time required varies depending on the complexity and customization, but it typically takes 40 to 80 hours spread over several weeks. This includes design, material preparation, stitching, and finishing, with each step done meticulously to ensure quality.

Are handmade shoes worth the investment?

Yes, handmade shoes are often worth the higher cost due to their superior materials, custom fit, and durability. They can last for decades with proper care, making them a cost-effective choice in the long run compared to frequently replacing cheaper shoes.

Can handmade shoes be repaired?

Absolutely. One of the key advantages of handmade shoes is their repairability. Techniques like Goodyear welting allow for easy resoling and minor repairs, extending the life of the shoes significantly. It's recommended to consult a professional cobbler for maintenance.