The Timeless Art of Traditional Shoe Making: Preserving Craftsmanship in a Modern World

The History and Evolution of Traditional Shoe Making

The art of traditional shoe making dates back thousands of years, with evidence found in ancient civilizations like Egypt and Rome. Initially, shoes were crafted from simple materials like leather and plant fibers, serving primarily for protection. Over centuries, techniques evolved, incorporating tools such as awls and lasts, and styles diversified to reflect cultural and social status. By the Middle Ages, guilds of shoemakers emerged in Europe, standardizing methods and passing down knowledge through apprenticeships. This historical foundation highlights how handmade shoes have always been more than just footwear—they are artifacts of human ingenuity and tradition.

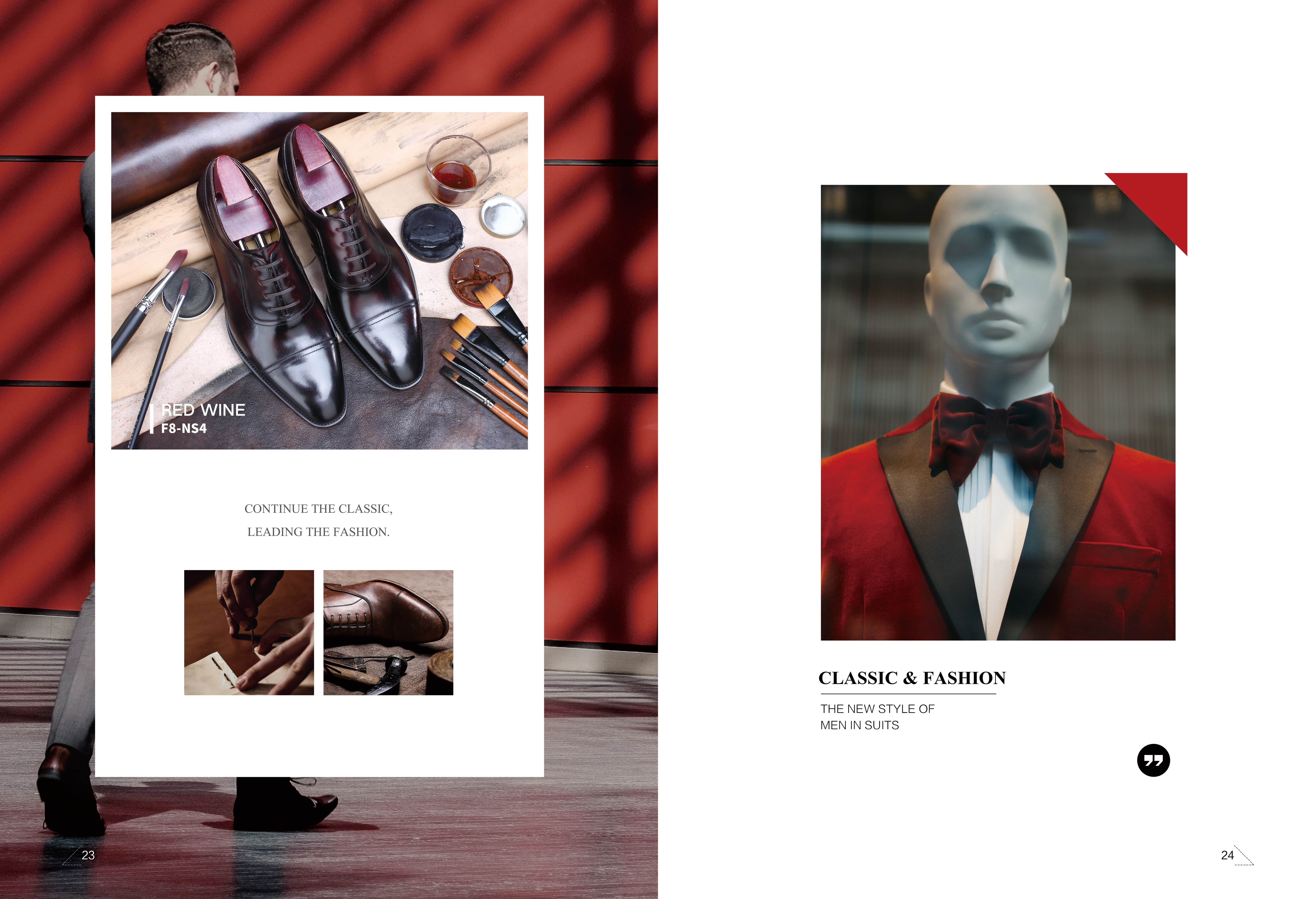

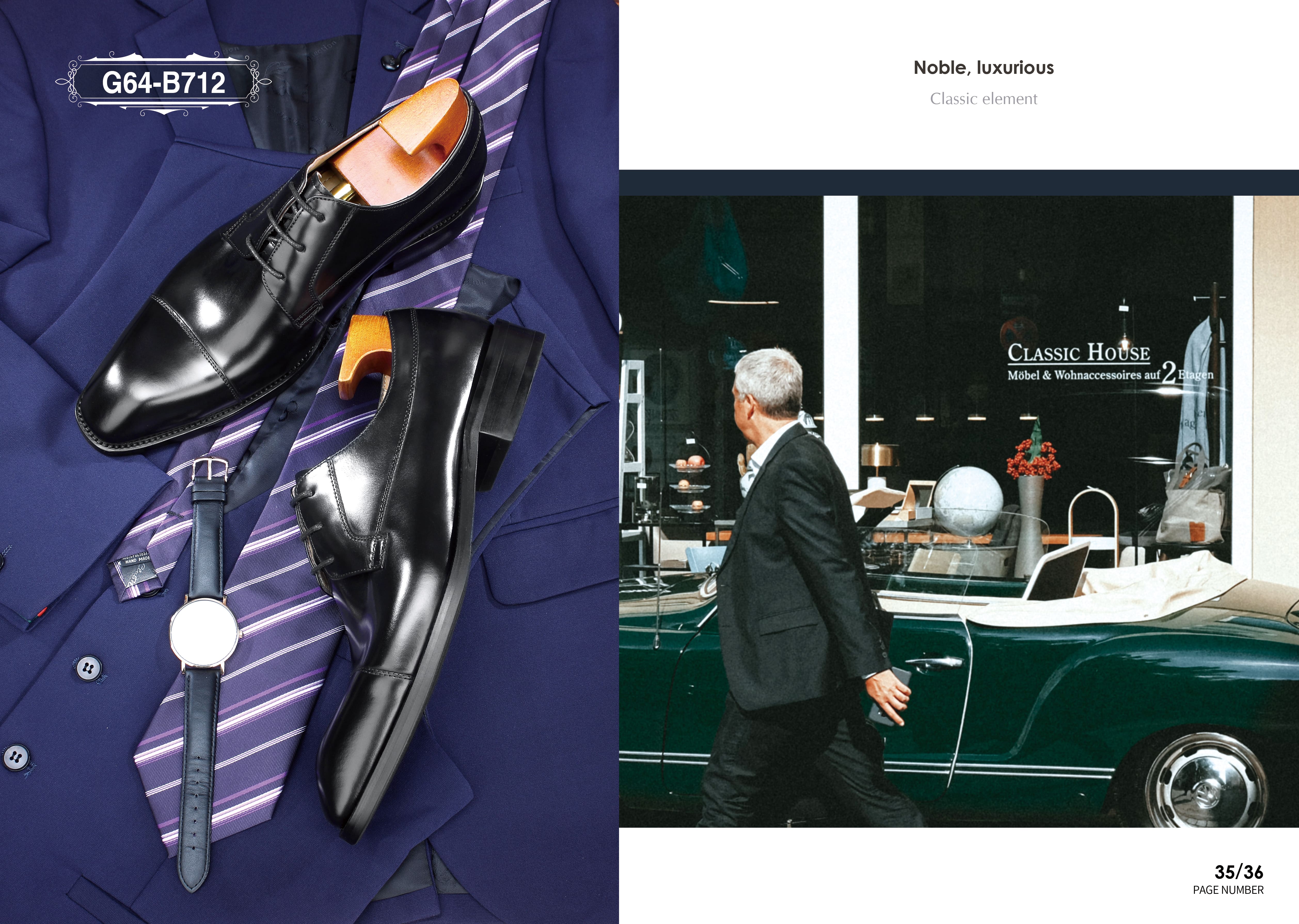

Key Techniques and Materials in Traditional Shoe Making

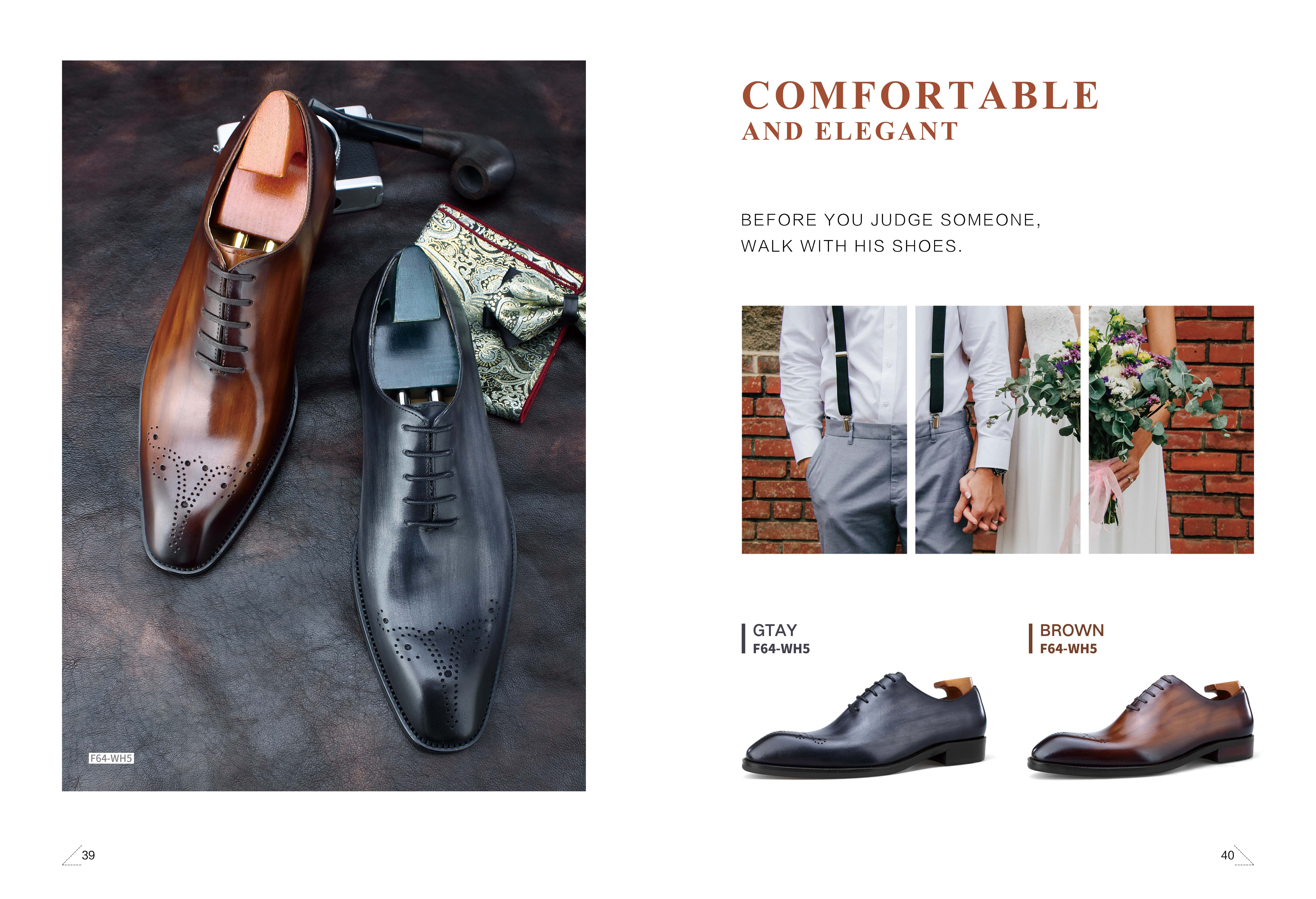

At the heart of traditional shoe making are meticulous techniques that ensure durability and comfort. The process typically begins with pattern cutting, where a shoemaker designs templates based on foot measurements. Next, leather selection is crucial; high-quality hides are chosen for their strength and flexibility. Stitching, often done by hand using waxed threads, provides resilience that machines cannot replicate. Lasting, or shaping the shoe over a wooden form, gives it structure, while sole attachment involves techniques like Goodyear welting for easy repairs. These methods require years of practice, emphasizing the craftsmanship involved in every pair.

Benefits of Traditional Shoe Making Over Mass Production

Choosing traditional shoe making offers numerous advantages over factory-made alternatives. Firstly, custom-fit shoes provide superior comfort, as they are tailored to an individual's foot shape, reducing issues like blisters or arch pain. Secondly, the use of premium materials like full-grain leather ensures longevity, often lasting decades with proper care. Environmentally, this approach is more sustainable, as it minimizes waste and avoids the carbon footprint of global supply chains. Moreover, supporting artisans helps preserve cultural heritage and local economies. In a world of fast fashion, handmade shoes represent a commitment to quality and ethical consumption.

Common Challenges and How to Overcome Them

Despite its merits, traditional shoe making faces challenges such as high costs and time-intensive labor. To address this, aspiring shoemakers can start with small projects or use reclaimed materials to reduce expenses. Learning through workshops or online courses can build skills gradually. For consumers, investing in a well-made pair can be cost-effective in the long run, considering their durability. Additionally, communities and organizations are promoting this craft through fairs and social media, raising awareness. By embracing these strategies, the tradition can thrive alongside modern innovations.

Frequently Asked Questions

What is the main difference between traditional and modern shoe making?

The primary difference lies in the process: traditional shoe making relies on hand tools and manual techniques, focusing on customization and durability, while modern methods use automated machinery for mass production, often prioritizing speed and lower costs over individual fit and longevity.

How long does it take to make a pair of traditional shoes?

It can take anywhere from 20 to 40 hours or more, depending on the complexity of the design and the shoemaker's experience. This includes steps like measuring, cutting, stitching, and finishing, each requiring careful attention to detail.

Are traditional shoes more expensive than store-bought ones?

Yes, they are generally more expensive due to the high-quality materials and labor-intensive process. However, their durability and custom fit often make them a better value over time, as they can last much longer than mass-produced shoes.

Can I learn traditional shoe making as a hobby?

Absolutely! Many enthusiasts start with beginner kits or local classes to learn basic skills. It requires patience and practice, but resources like online tutorials and community workshops make it accessible for hobbyists interested in preserving this craft.