The Timeless Art of Italian Shoe Craftsmanship: A Journey Through Heritage and Excellence

The Foundations of Italian Shoe Craftsmanship

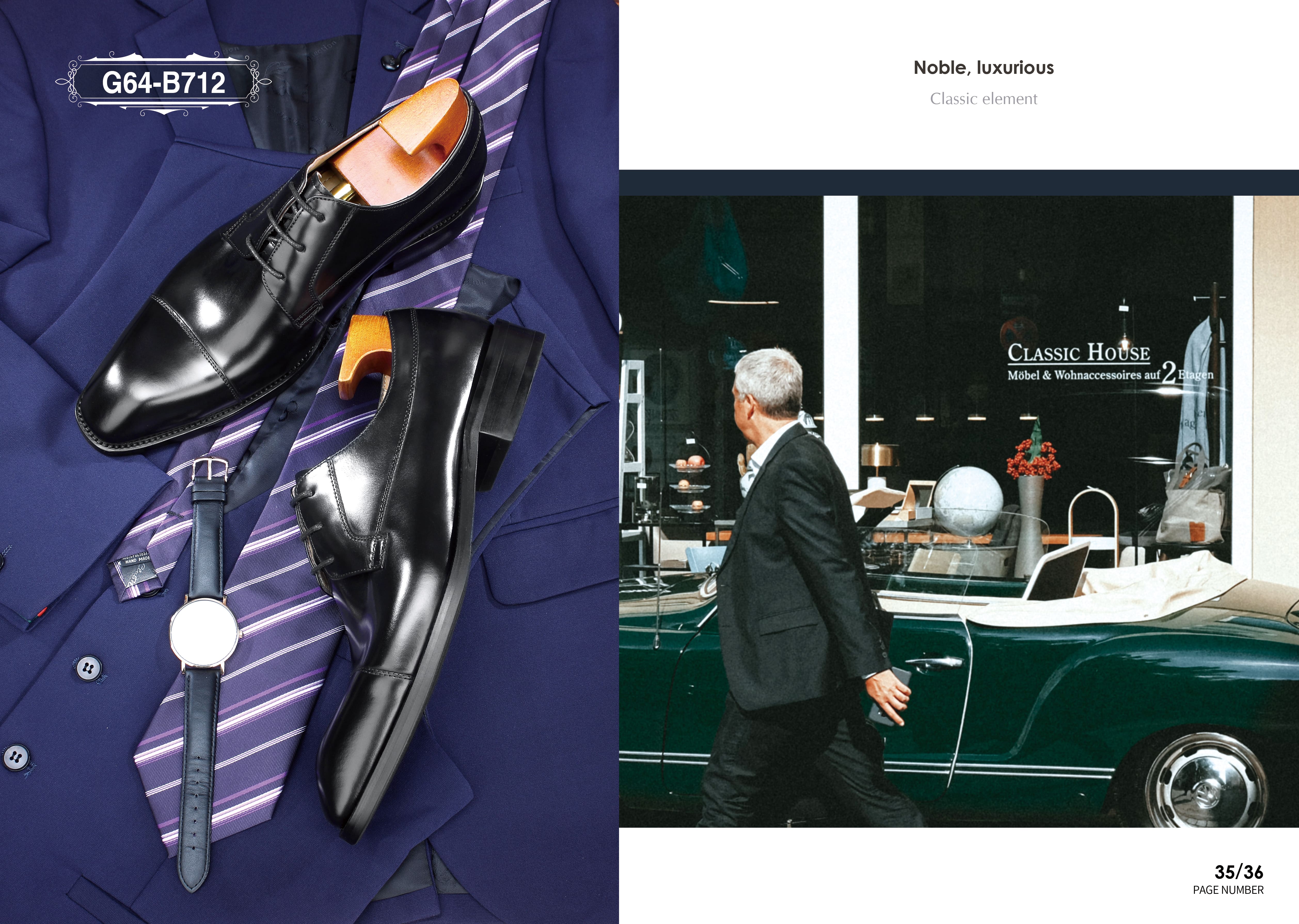

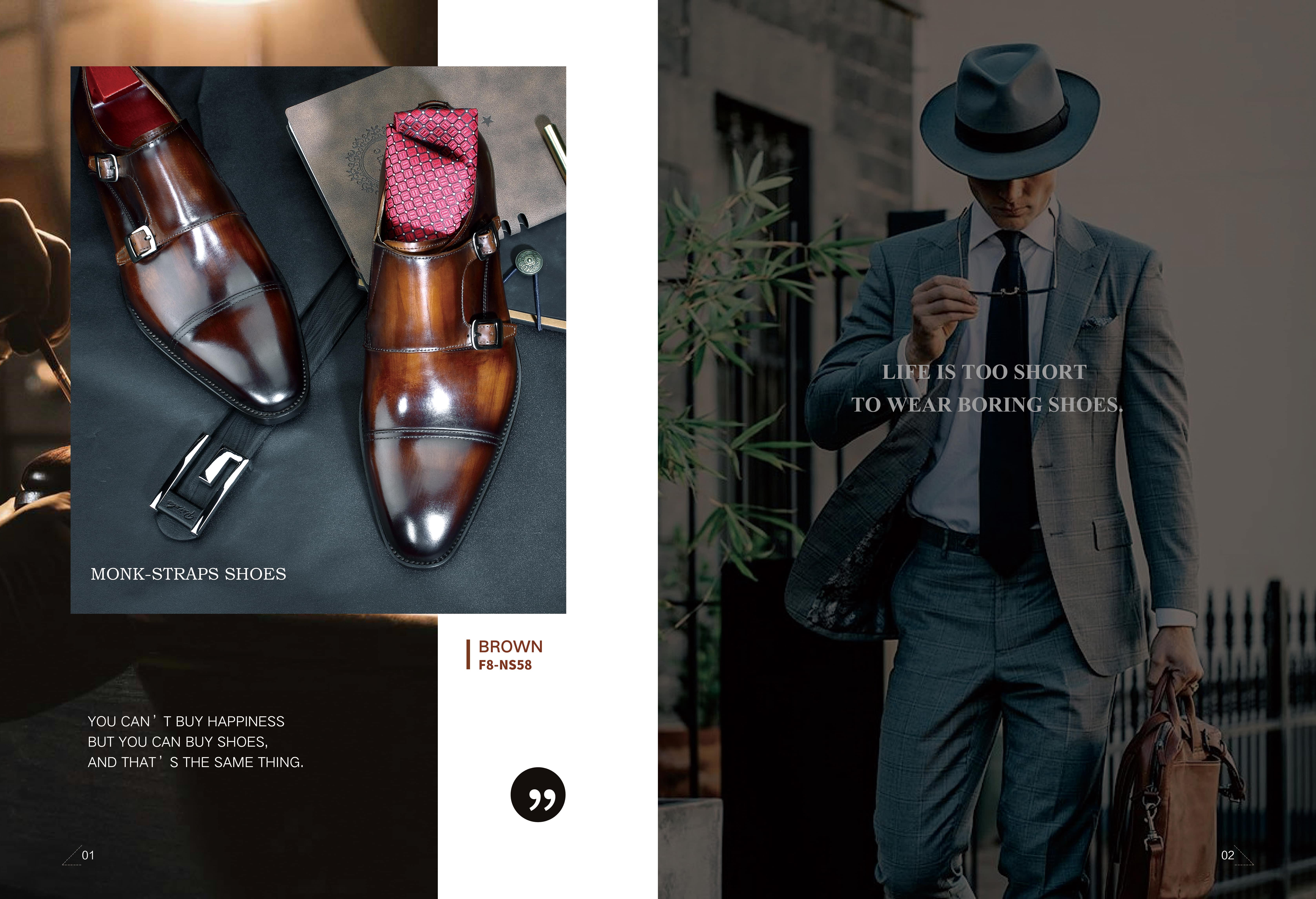

Italian shoe craftsmanship has deep roots in history, dating back to the Renaissance period when skilled artisans began perfecting the art of shoemaking. The process starts with the selection of high-quality materials, such as fine leather from Tuscany or calfskin from Northern Italy. Each piece is carefully inspected to ensure it meets strict standards for durability and aesthetics. Traditional techniques, like hand-stitching and last-making, are passed down through generations, preserving a legacy of excellence. This foundation sets Italian shoes apart, making them not just footwear but works of art that blend functionality with beauty.

Key Techniques and Processes

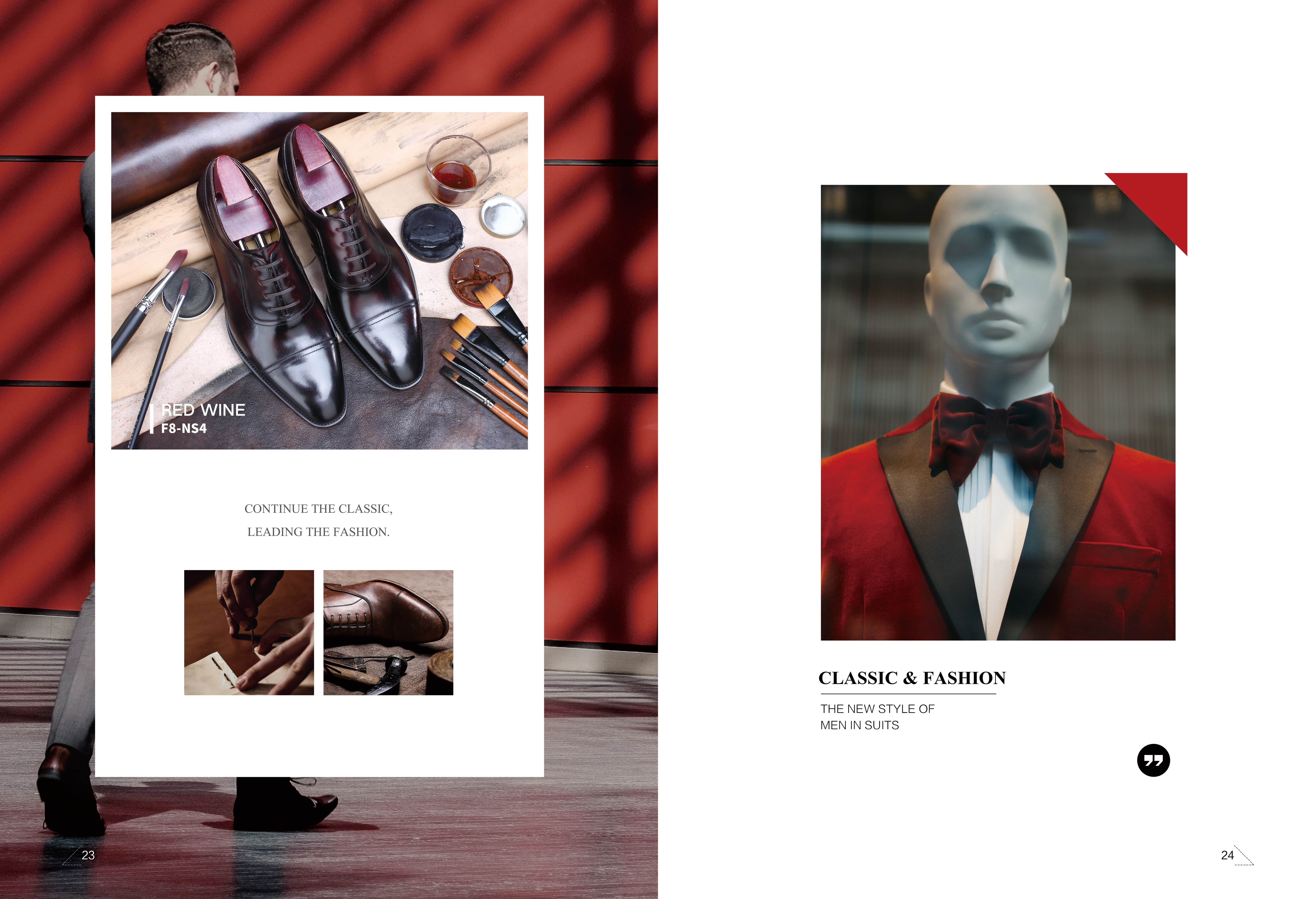

One of the hallmarks of Italian shoe craftsmanship is the use of the Goodyear welt construction, a method that allows for easy resoling and enhances longevity. Artisans spend hours on tasks like pattern cutting, where precision is crucial to achieve a perfect fit. The assembly phase involves meticulous handwork, including gluing, stitching, and shaping the shoe around a wooden last. Finishing touches, such as polishing and burnishing, add a luxurious sheen. These processes require years of training and a keen eye for detail, ensuring that every pair meets the highest standards of quality and comfort.

Materials and Sustainability

Italian shoemakers prioritize sustainable practices by sourcing materials from local tanneries that adhere to eco-friendly methods. Vegetable-tanned leather is a popular choice, as it ages beautifully and reduces environmental impact. Innovations in material science have also led to the use of recycled fabrics and biodegradable components. By balancing tradition with modern sustainability, Italian craftsmanship not only produces durable shoes but also contributes to a greener future. This commitment to quality and ethics makes Italian shoes a wise investment for conscious consumers.

Common Challenges and Solutions

Despite its prestige, Italian shoe craftsmanship faces challenges like rising costs and competition from mass-produced alternatives. To address this, many artisans focus on niche markets, offering custom-made shoes that cater to individual preferences. Embracing technology, such as 3D scanning for precise measurements, helps streamline production while maintaining artisanal quality. Additionally, educating consumers about the value of handmade shoes can foster appreciation and support for this tradition. By adapting to modern demands without compromising on core principles, Italian shoemakers continue to thrive in a global market.

Frequently Asked Questions

What makes Italian shoes more expensive than others?

Italian shoes are often pricier due to the high cost of premium materials, extensive hand labor, and the time-intensive processes involved. Each pair is crafted with meticulous attention to detail, ensuring superior durability, comfort, and style that mass-produced shoes cannot match.

How can I care for my Italian leather shoes to extend their lifespan?

To maintain Italian leather shoes, regularly clean them with a soft cloth and use conditioners to prevent drying. Store them in a cool, dry place with shoe trees to retain shape, and avoid wearing them in harsh weather. Professional resoling and polishing can also help preserve their quality over time.

Are Italian shoes suitable for everyday wear?

Yes, many Italian shoes are designed for durability and comfort, making them suitable for daily use. However, it's advisable to rotate pairs to reduce wear and allow materials to rest, ensuring they last longer while maintaining their elegant appearance.